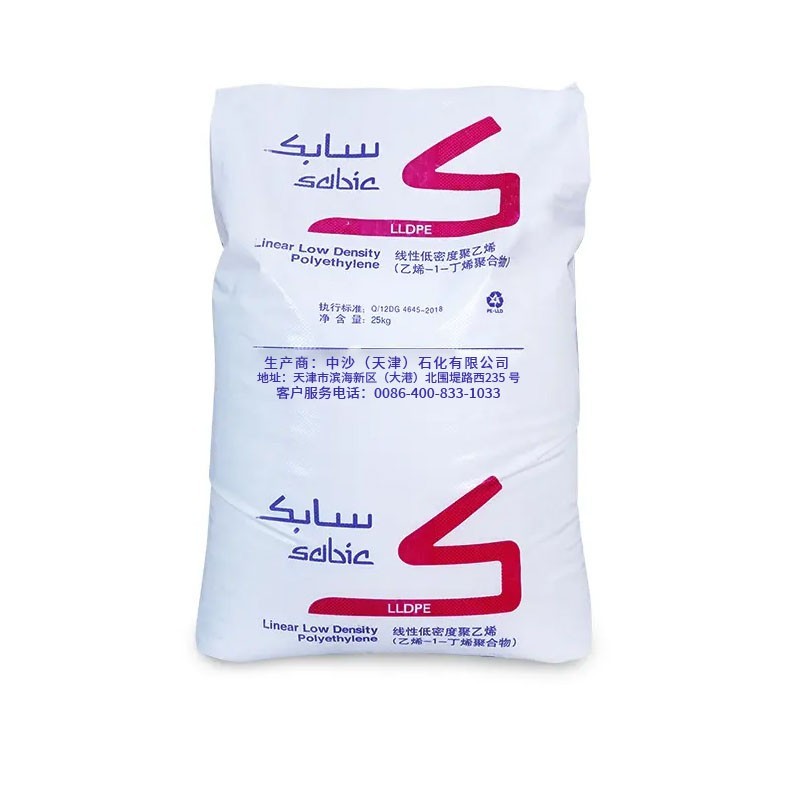

Sabic 920NT LLDPE Film

Trading Port:Huangpu / Ningbo / Shanghai / Qingdao

Lead Time:30

US$ 500

/ Kg

1 Kg

(Min.Order)

Payment Terms:

L/C,T/T

Samples:

Beijing TDD E-commerce Co., Ltd

Online Store

11 Yrs

CN Supplier

Main Products

PVC Resin , PP , PE , Pet , Titanium Dioxide , Pigment , Car Tire

You Might Also Like

Basic Info.

Company Overview

B2B cross-border e-commerce platform and the core subsidiary of Guolian Co., Ltd. (603613. Sh). Specialized in raw material&industrial products for more than 20 years and provide wholesale products for customers worldwide. Now the main running industry chain contains: Pigment industry chain, Titanium industry chain, solvent industry chain, resin industry chain, lubricating oil industry chain, carbon black industry chain, packaging industry chain, medical industry chain etc.

More

Basic Information

| Company Name | Beijing TDD E-commerce Co., Ltd | Country | China |

| Business Type | Online Store | Company Size | 2000 |

| Established | December 18, 2014 | ||

| Address | Building No.3, Area 6, No.188, West of South Forth Ring Rd, Beijing, China | ||

| Main Products | PVC Resin , PP , PE , Pet , Titanium Dioxide , Pigment , Car Tire | ||

| International Commercial Terms(Incoterms): | FOB, CFR, CIF, FCA | ||

| Terms of Payment: | LC, T/T, D/P | ||

| Average Lead Time: | Peak Season Lead Time: one month, Off Season Lead Time: within 15 workdays | ||

| Number of Foreign Trading Staff: | 20~40 People | ||

| Main Markets: | Southeast Asia, Africa, Mid East | ||

| Nearest Port: | Tianjin,Qingdao,Shanghai | ||

| Import & Export Mode: | Have Own Export License | ||

Company Introduction