Calcium carbonate filled modified polyethylene (PE) is not effective? There are many ways!

Polyethylene (PE) is one of the plastics with the highest attention in industrial production. It has excellent low-temperature resistance, resistance to most acids and alkalis, good chemical stability, rapid molding, and strong operability. It is widely used in packaging, building materials, automotive, biological, and other fields. However, due to its poor heat resistance and relatively low mechanical properties, its further application is limited.

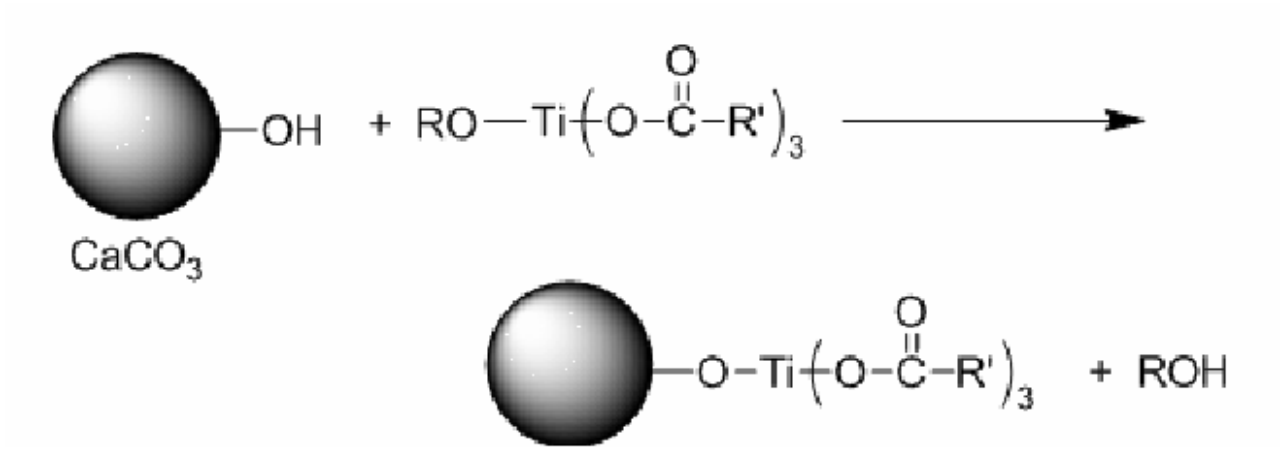

Ultrafine calcium carbonate (CaCO3) has a small particle size and good dispersibility, which has the advantages of reducing pores and voids in plastics and making the shrinkage of plastics more uniform. Filling it in plastics such as polyethylene, polystyrene, polyvinyl chloride, and polypropylene can improve the hardness, dimensional stability, and rigidity of plastic products.

However, a large number of studies have shown that only using calcium carbonate or another filler to fill modified polymers or modify other materials often does not achieve the optimal effect, and the performance improvement is relatively simple. The composite modification of various non-metallic mineral powders often has better effects and can improve the comprehensive performance of materials. Currently, research and application are also increasing. Studies by Yang Changyou and others have shown that nano-CaCO3 can improve the compatibility and thermal stability of polyethylene composites, and bagasse fiber (BF) can improve the crystallinity and toughness of the composites, both of which can effectively improve the mechanical and mechanical properties of the composites.

Xinweiye Brand Calcium Carbonate 1250mesh