The difference among PVC, PP and PE

一、.The introduction and application of PVC

Polyvinyl Chloride (PVC) is one of the most commonly used thermoplastic polymers worldwide (next to only a few more widely used plastics like PET and P.P.). It is naturally white and very brittle (before the additions of plasticizers) plastic. PVC has been around longer than most plastics, first synthesized in 1872 and commercially produced by B.F. Goodrich Company in the 1920s. It is used most commonly in the construction industry and is also used for signs, healthcare applications, and fiber for clothing.

二、The introduction and application of PP

Polypropylene (PP) is a thermoplastic “addition polymer” made from the combination of propylene monomers. It is used in a variety of applications to include packaging for consumer products, plastic parts for various industries including the automotive industry, special devices like living hinges, and textiles.

三、The introduction and application of PE

Polyethylene (PE) is the most widely used thermoplastic polymer for fabricated parts and components. It is available in a variety of grades and formulations to suit different needs. In general, polyethylenes offer excellent chemical and impact resistance, electrical properties and low coefficient of friction. It is considered a dielectric material. In addition, polyethylenes are lightweight, easily processed and offer near-zero moisture absorption. See details of its material properties in the chart below.

So what the difference among them?

1. FLEXIBILITY

PROTECTION’S RESISTANCE TO IMPACT

PVC has a highly enhanced elastic behavior, and consequently, it always returns to its original shape;

Other materials lose color if too stimulated and get deformed permanently.

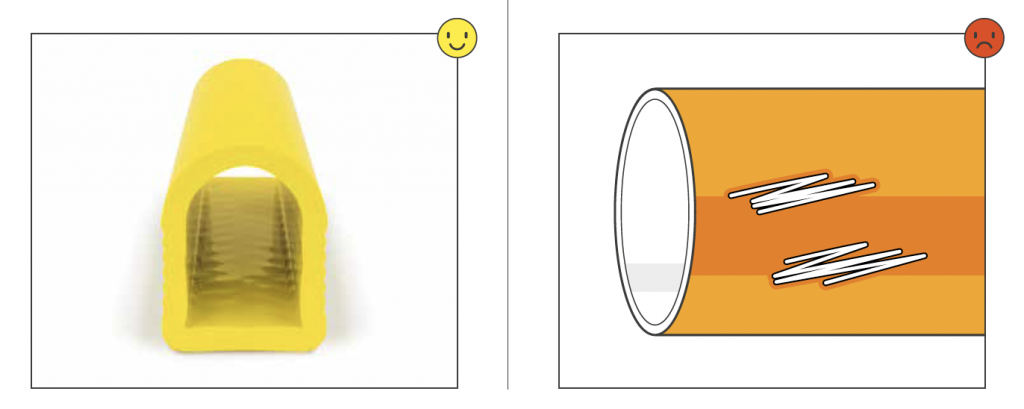

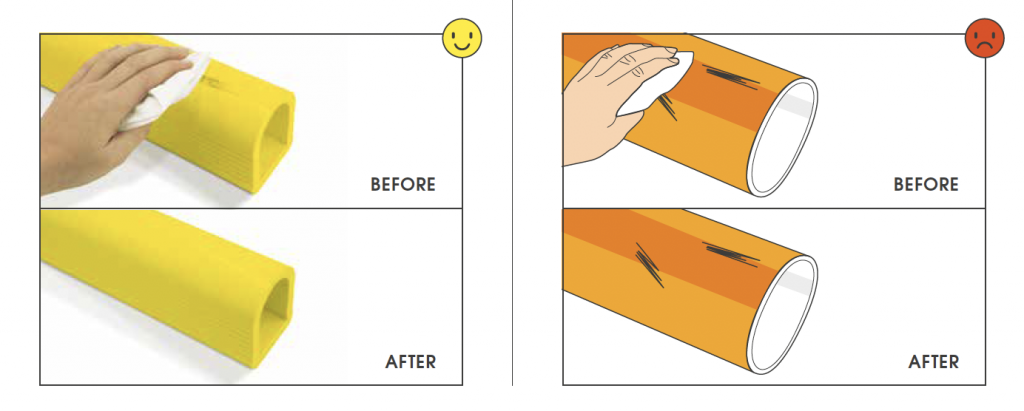

2.SCRATCHES

OUR PVC IS RESISTANT TO ANY SCRATCHES

PVC material is entirely pigmented and difficult to scratch thanks to its special surface;

Other materials only have the upper layer pigmented, and scratches are evident and not coverable.

3.EASY CLEANING

CLEANING DIFFERENCE BETWEEN GLOBE’S PVC AND PE/PP

Globe’s PVC surface is easy cleaning even just with water;

The polyethylene and polypropylene materials absorb dirty and consequently, it is impossible to clean them.

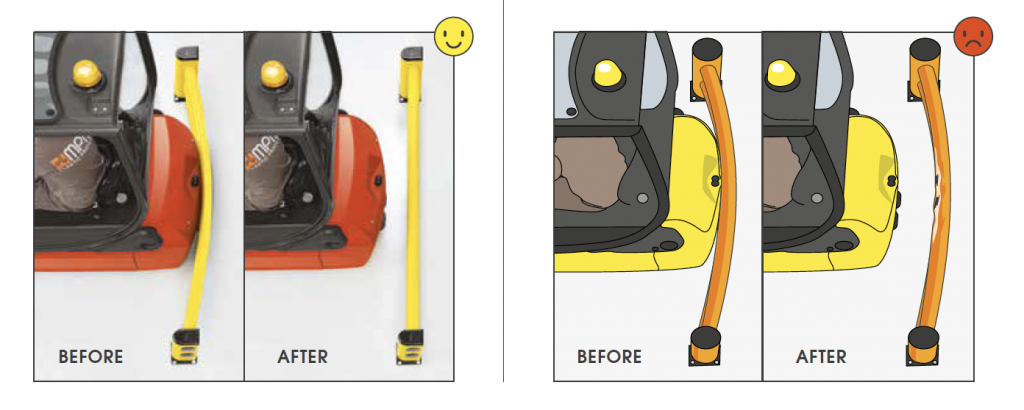

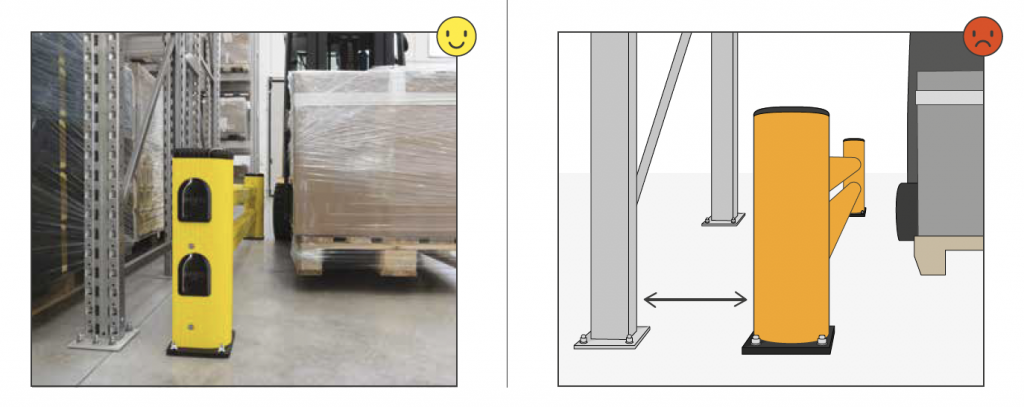

4.SAVE SPACE

DISTANCE FROM THE PROTECTED AREA AND IMPACT SURFACE

Globe’s PVC protections have compact dimensions and therefore need a small distance from the shelves;

The polyethylene and polypropylene materials need bigger dimensions and a larger distance from the racks to protect equally.

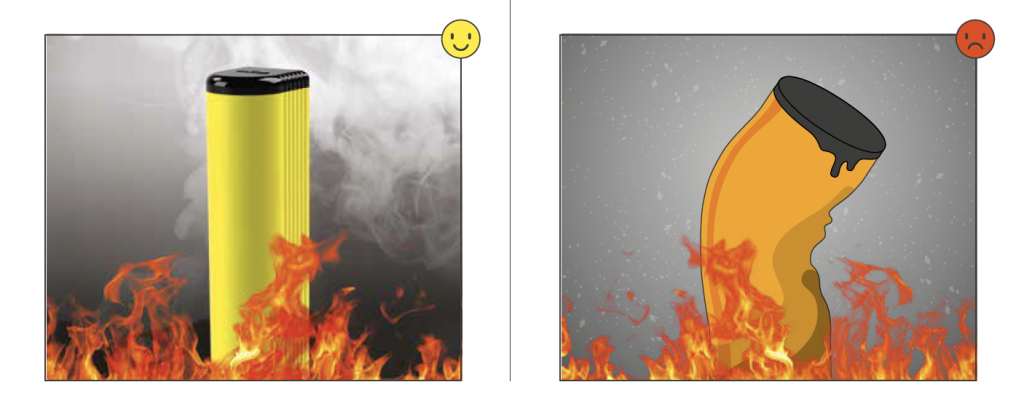

5.FIRE RESISTANT

FIRE BEHAVIOUR ACCORDING TO UL-94

Globe’s PVC type is v0; this means that it is self-extinguishing in case of fire;

Polyethylene and polypropylene are not HB materials, consequently, they do not resist fire and burn immediately.