Effects of Titanium Dioxide Types on Properties of ABS Resin

Four commonly used titanium dioxides prepared by different manufacturing processes have different effects on the Lab value, mechanical properties and processability of ABS resins. The research results show that after adding titanium dioxide, the brightness of ABS resin has been significantly improved. Titanium dioxide has little effect on the tensile properties and bending properties of ABS resin, but the addition of titanium dioxide can greatly reduce the notched impact of ABS resin. strength. Compared with the titanium dioxide prepared by the sulfuric acid method, the titanium dioxide prepared by the chlorination method has a greater increase in the whiteness of ABS, and the comprehensive mechanical properties are better.

ABS resin is one of the most widely used engineering plastics in the market. It consists of a terpolymer composed of styrene (S), butadiene (B), and acrylonitrile (A). Among them, acrylonitrile has strong chemical resistance and hardness, and butadiene has high toughness. Styrene provides excellent processing fluidity and colorability. Therefore, ABS resin has both rigid and tough mechanical properties at the same time. ABS resin is widely used in construction, machinery, electrical and electronic, automobile, home appliances and other manufacturing industries and chemical industries.

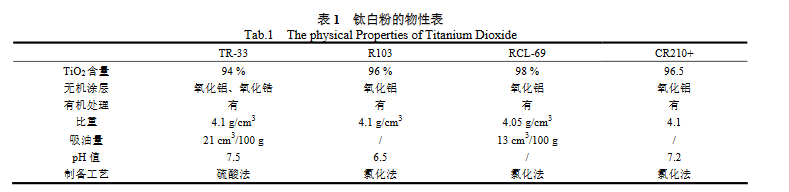

The experimenter will focus on the commonly used chlorination and sulfuric acid vegetation titanium dioxide grades and the commonly used ABS grades in the plastics industry as the research objects to study the brightness, yellowness, mechanical properties, The difference in processing fluidity is used as a data reference for future product design. In the experiment, two kinds of ABS and four kinds of titanium dioxide were selected, which are: Titanium dioxide grade: TR-33; R103; RCL-69; CR210+ ABS grade: ABS DG-417, Tianjin Dagu Chemical Co., Ltd.; ABS 750N SW, Kumho Chemical Co., Ltd., Korea.

In conclusion:

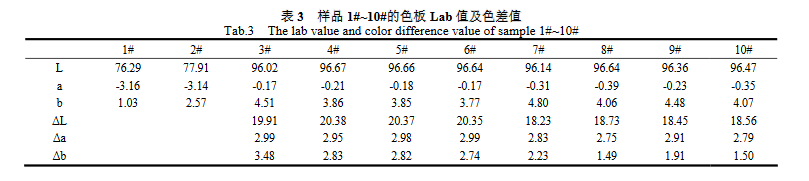

1. The influence of titanium dioxide type on the Lab value of ABS resin

As shown in the figure, after adding titanium dioxide, the brightness of the ABS sample increases, and the a and b values both increase to varying degrees;

In other words, the improvement of the brightness of ABS DG-417 by R103, RCL-69 and CR210+ prepared by the chlorination method is obviously greater than that of the TR-33 prepared by the sulfuric acid method on the brightness of ABS DG-417, and the same is true of ABS 750 N SW.

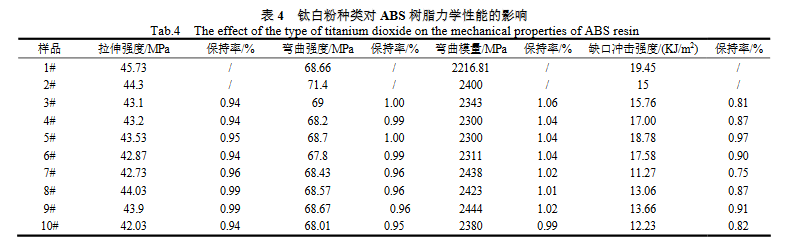

2. The influence of titanium dioxide type on the mechanical properties of ABS resin

Since ABS is often used as a structural material, its mechanical properties play a crucial role in its application scenarios. The effect of different types of titanium dioxide on the mechanical properties of ABS matrix is shown in the figure.

After the four kinds of titanium dioxide were added to ABS DG-417, the tensile strength decreased slightly, and the flexural strength and flexural modulus increased slightly, but the notched impact strength lost a lot. Similarly, the addition of titanium dioxide has little effect on the tensile properties and flexural properties of the ABS 750 N SW matrix, but has a greater damage to the notched impact strength. This may be due to the poor compatibility between titanium dioxide and the matrix, which is easy to cause material performance defects; when subjected to external force, a stress concentration point is formed, resulting in a lower impact strength of the material. But in the same matrix, after adding titanium dioxide R103, RCL-69, CR210+, the performance retention rate of the product is much better than TR-33.

3. The influence of titanium dioxide type on the processing performance of ABS resin

As can be seen from the figure below, whether in the ABS DG-417 system or the ABS 750 N SW system, adding titanium dioxide will increase the melt flow index and make the processability better.

In conclusion: After mixing titanium dioxide and ABS resin, the brightness of the sample was significantly increased, and the titanium dioxide prepared by the chlorination method improved the brightness of ABS resin more excellently. Titanium dioxide has little effect on the tensile properties and bending properties of ABS resin, but the addition of titanium dioxide can greatly reduce the notched impact strength of ABS resin. However, the effects of titanium dioxide prepared by different production processes on the impact strength of ABS are indeed very different. In general, the titanium dioxide prepared by the chlorination method greatly improves the whiteness of ABS and has better comprehensive mechanical properties.