Current situation with Titanium pipes

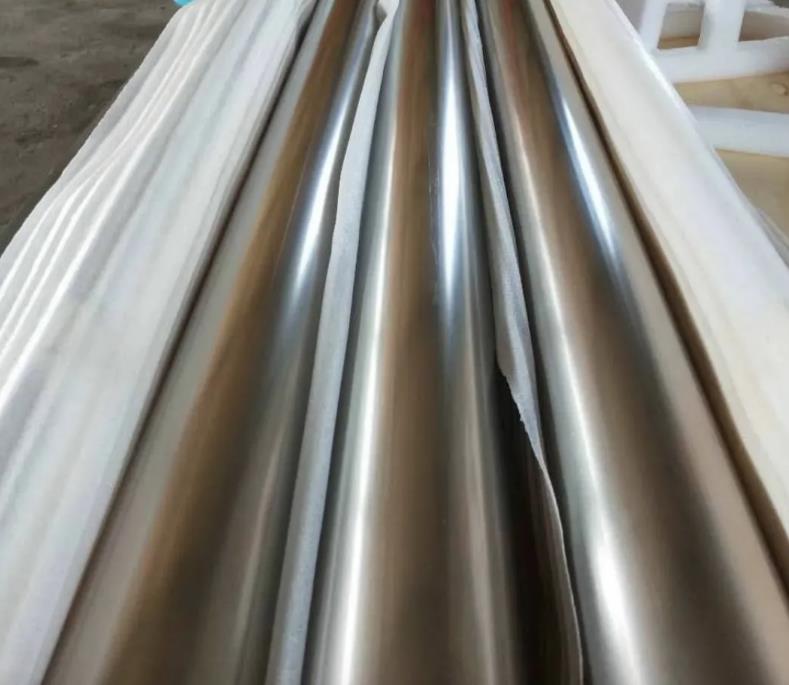

Titanium and titanium alloy longitudinally welded pipes (referred to as "titanium welded pipes") are formed by crimping and rolling titanium and titanium alloy coils or wide plates into tubular shapes and then welding them. American titanium alloy grades mainly include Gr.1, Gr.2 and Gr.12, and domestic titanium alloy grades mainly include TA1, TA2 and TA10.

The production process of titanium welded pipe is as follows: titanium strip uncoiling → shear butt welding → looper storage → titanium strip cleaning → tube forming → welding → welding seam eddy current inspection → predetermined diameter → online annealing → fine sizing/straightening → Eddy current inspection → laser diameter measurement → online coding → fixed-length cutting → ultrasonic inspection → precisely fixed length/flat head → air tightness test → finished product inspection → packing and storage.

The development of the domestic titanium welded pipe industry in recent years

Due to the constraints of raw materials and processing technology, the production technology of titanium welded pipe has been in the hands of professional manufacturers in Japan, the United States, France, Russia, and other countries for many years. Compared with other titanium processed products, the development of China's titanium welded pipes started late, and the early development was relatively slow. Although titanium seamless pipe started early in China, its application is limited due to the many processing procedures, long production cycle, low efficiency, and high cost of titanium seamless pipe. The production efficiency and yield rate of titanium welded pipe are high, and the performance of tube expansion and bending is similar to that of seamless tubes. Therefore, the amount of titanium welded tubes at home and abroad is increasing year by year, and the application in condensers of power stations is increasing.

In the early stage of the development of titanium welded pipe, although China introduced a complete automatic production line for small diameter titanium welded pipes from abroad, which ended China’s history of not being able to produce titanium welded pipes, at that time, the raw material for the production of titanium welded pipes in China was completely dependent on imports and could not be provided. The strip blanks for thin-walled titanium welded pipes and the high sales price of foreign titanium coils have inhibited the production of domestic titanium welded pipes. In addition, due to the multiple influences of technology introduction and digestion and difficulty in raw material procurement, domestic titanium welded pipes have not really achieved mass production capacity, and the domestic titanium welded pipe market was not really formed at that time.

In the past ten years, the rapid development of China's titanium welded pipe industry is mainly due to the major breakthroughs made in the production technology of titanium welded pipe raw material—titanium coils, and the technical performance indicators and quality stability of domestic cold and hot rolled titanium coils. It can meet the requirements of titanium welded pipe. Xiangtou Jintian Titanium Metal Co., Ltd., a subsidiary of Hunan Xiangtou Jintian Technology Group, developed China’s first wide-width hot-rolled titanium strip in 2007 through the “titanium steel joint model”; in 2008, it developed cold-rolled titanium strip. This broke the monopoly of Japan and the United States in this field, provided raw material support for China's titanium welded pipe industry, and then domestically made titanium welded pipes came into being.

Xi'an Baotai Meite Farino Welded Pipe Co., Ltd., a joint venture between Baoti Group Co., Ltd. and many domestic and foreign companies, was officially put into operation in 2007. The commissioning of this production line has promoted the progress of domestic titanium welded pipe production technology. With the breakthrough of Baoti Group Co., Ltd. in titanium cold-rolled strip technology in 2011, Xi'an Baotai Meite Farino Welded Pipe Co., Ltd. also realized the mass production of domestic titanium cold-rolled strip.

In recent years, with the overall progress of the titanium industry, the expansion of sponge titanium production capacity, and the expansion of titanium processing capacity such as titanium strip coils, the downstream titanium welded pipe industry has also made considerable development. Since 2008, many titanium welded pipe production lines have been built in China. The expansion of titanium welded pipe production capacity and the slowdown in the development of the titanium industry have intensified competition among titanium welded pipe companies. At present, in addition to companies with a complete titanium industry chain such as Xiangtou Jintian Technology Group, other titanium welded pipe companies, as well as many companies with stainless steel pipes and rare metal pipes as their main industries, are also promoting the progress of the titanium welded pipe industry. Titanium welded pipe companies are paying more and more attention to the development of new technologies and the development of differentiation.

The application fields of titanium welded pipes are constantly expanding. Titanium welded pipes have become the first choice for replacing stainless steel pipes, copper-nickel alloy pipes, and titanium seamless pipes in many industries. After several years of development, domestic titanium welded pipe has broken through a series of key processes and technical bottlenecks, and has been widely used in electric power, air conditioning, seawater desalination, water treatment equipment, and other fields. In addition, domestic titanium welded pipes have also been exported in batches. It can be seen that the production technology and quality level of domestic titanium welded pipes have been greatly improved.